autoclave horizontal industrial for pulley rubber vulcanization

Product Description

Product Description Product Application Autoclave for shoes sole molding vulcanization is under 1.2MPa, belongs to low pressure vessel. Single walled cylindrical structure, and it is made up of tank body, autoclave door, switch, locking device, heating device and other auxiliary device. Tooth type quickly opening structure.

Main application

Main application

Mainly used for rubber products, hoses, rubber roller and other vulcanization

1. rubber vulcanizing autoclave is widely cured with rubber products for mechanical properties such as: new tire curing, tire refurbishment, hose, roller, cable, pipe vulcanization

2. Capsules, rubber sheet, rubber gloves, rubber shoes, tape, lined rubber, rubber cloth, rubber and other products vulcanization.

3. Rubber vulcanizing autoclave is also widely used for wood dry, hydrolysis, wood dipping, wood shaping, oxidizing, autoclave, wood cooking, wood impregnation and wood drying, etc.

Main Features 1.Design of tank gate. Manual opening, electrical opening and pneumatic opening.

Main Features 1.Design of tank gate. Manual opening, electrical opening and pneumatic opening.

2. High safety. Six sets of safety interlocks is adopted, includeautomatic pressure safety interlocking, pressure automatic control, manual safety, manual vent valve, high pressure alarm, automatic safety valve. Tank gate will not open as long as there have pressure inside of the chamber, remove potential safety hazard caused by mistake operation.

3. Inflatable seal. It can seal once close door and the pot inflate, gate cannot open only when pressure relief totally, seal ring's service life is more than 1 year, it will not wear in this period.

4. Good heat preservation effect.Use aluminum silicate rock wool with steel plate support outside,which can ensure heat won't volatilize and shape won't transform, insulation effect can keep 10 years.

5.Automatic control: All main process can finished accurately by PLC control system, include heating process, heat preservation process, vulcanizing process, these process can realized just turn on the switch, which can save labor costs and ensure quality of product.

Working Principle

Working Principle

1. It's a new type of vulcanizing. Temperature, pressure, curing time is automatic controlled. Using convenient, safe and environmental protection and no pollution.

2. Stainless electro-thermal tube with new type magnesium oxide insulation material to heating fast and extend life.

3. The electric tube is divided into three groups of switches, after the working temperature is reached, only one group of vulcanization insulation is retained.

4. Electric tube external terminal to avoid built-in wiring point ignition, safe and reliable.

5. The fan in the tank back and forth, the heat from the front and back evenly spread. High temperature air through a special air duct in the tank back and forth in the medium speed cycle to ensure that tank temperature uniformity, no dead ends. To solve the temperature and pressure caused by uneven product quality problems.

6. After setting the working procedures, the control system automatically heat up, maintain temperature, curing and other work, after the end of the vulcanization, the sound and light alarm and cut off the power automatically.

Those rubber vulcanizing autoclave in the chart are standard configurations.

We also can customize the rubber vulcanizing autoclave according to your specific requirements or your drawing.

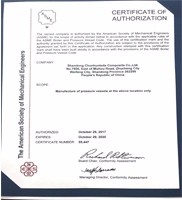

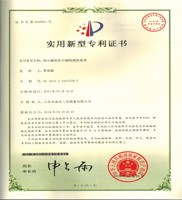

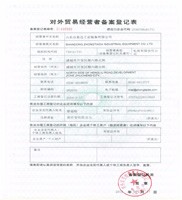

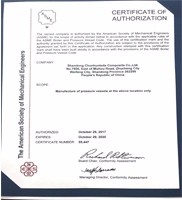

Certifications

Detailed Images

Detailed Images  Machine Parts Name: Autoclave Capped Brand: ZTD Original: China Autoclave capped is an indispensable part of the autoclave, and it is the end cap of the autoclave and is a major pressure-bearing part of the autoclave. Main Features Name:Flange

Machine Parts Name: Autoclave Capped Brand: ZTD Original: China Autoclave capped is an indispensable part of the autoclave, and it is the end cap of the autoclave and is a major pressure-bearing part of the autoclave. Main Features Name:Flange

Brand: ZTD

Original: China

Connect autoclave capped and autoclave cylinder

Machine Parts Name: Control Box

Machine Parts Name: Control Box

Brand:ZTD

Original: China

Control of the entire distribution system is a major part of the distribution box function

Main Features Name: Electric pipe

Brand: ZTD

Original: China

Produce heat source and make curing for rubber pulley,rubber hose, rubber shoes, rubber gloves, rubber v-belt and so on. The Accessories of the Rubber Vulcanization Autoclave

The Accessories of the Rubber Vulcanization Autoclave

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. If you are interested in our products want to consult us, you can freely call us or send us Email at any time, we will be very glad to serve you. Welcome to visit our factory in Zhucheng City of China. Packing & Delivery

If you are interested in our products want to consult us, you can freely call us or send us Email at any time, we will be very glad to serve you. Welcome to visit our factory in Zhucheng City of China. Packing & Delivery  We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

Before delivery, our professional technician will do trial run for each product to check until everything is functional, you also can come to our factory and test our machine together with us.

When loading, our workers will fix the rubber autoclave tightly with wire rope so that the autoclave can't move in the container.

Our Company Shandong Zhongtaida Industrial Equipment Co. Ltd. is one of the largest and most professional manufacturers of pressure vessel vulcanizing equipment in China. Our company has complete qualifications, advanced equipment, strong technical force and complete testing means with stable quality assurance system. Main products: all kinds of small, medium and large full automatic, semi automatic, electric heating vulcanization, steam vulcanization, electric steam vulcanization , giant vulcanization, vertical vulcanization, indirect heating vulcanization, rubber vulcanization, tire retreading vulcanizing, rubber covered roller vulcanization, rubber hose vulcanization, rubber capsule vulcanization, rubber shoes vulcanization, belt vulcanization, conveyor belt vulcanization , pipeline vulcanization, cable vulcanizing tank, steam equipment and other equipment. Our company is a modern new enterprise which integrates design, manufacture and installation in one whole.

More vulcanization autoclave detail specs please check our website,

More vulcanization autoclave detail specs please check our website,

www.cnmosen.com

www.CN-autoclave.com

www.ztdlhg.com

Kiki's more contact

whatsapp / wechat: +86 13371074339

Line: 86 18765175123

autoclave for shoes sole molding vulcanization, autoclave for shoes sole molding, vulcanization autoclave, shoes vulcanization autoclave autoclave horizontal industrial for pulley rubber vulcanization, autoclave horizontal industrial, pulley rubber vulcanization, pulley vulcanization autoclave

Contact us if you need more details on autoclave horizontal industrial. We are ready to answer your questions on packaging, logistics, certification or any other aspects about pulley rubber vulcanization、pulley vulcanization autoclave. If these products fail to match your need, please contact us and we would like to provide relevant information.

Main application

Main application Mainly used for rubber products, hoses, rubber roller and other vulcanization

1. rubber vulcanizing autoclave is widely cured with rubber products for mechanical properties such as: new tire curing, tire refurbishment, hose, roller, cable, pipe vulcanization

2. Capsules, rubber sheet, rubber gloves, rubber shoes, tape, lined rubber, rubber cloth, rubber and other products vulcanization.

3. Rubber vulcanizing autoclave is also widely used for wood dry, hydrolysis, wood dipping, wood shaping, oxidizing, autoclave, wood cooking, wood impregnation and wood drying, etc.

Main Features 1.Design of tank gate. Manual opening, electrical opening and pneumatic opening.

Main Features 1.Design of tank gate. Manual opening, electrical opening and pneumatic opening.2. High safety. Six sets of safety interlocks is adopted, includeautomatic pressure safety interlocking, pressure automatic control, manual safety, manual vent valve, high pressure alarm, automatic safety valve. Tank gate will not open as long as there have pressure inside of the chamber, remove potential safety hazard caused by mistake operation.

3. Inflatable seal. It can seal once close door and the pot inflate, gate cannot open only when pressure relief totally, seal ring's service life is more than 1 year, it will not wear in this period.

4. Good heat preservation effect.Use aluminum silicate rock wool with steel plate support outside,which can ensure heat won't volatilize and shape won't transform, insulation effect can keep 10 years.

5.Automatic control: All main process can finished accurately by PLC control system, include heating process, heat preservation process, vulcanizing process, these process can realized just turn on the switch, which can save labor costs and ensure quality of product.

Working Principle

Working Principle1. It's a new type of vulcanizing. Temperature, pressure, curing time is automatic controlled. Using convenient, safe and environmental protection and no pollution.

2. Stainless electro-thermal tube with new type magnesium oxide insulation material to heating fast and extend life.

3. The electric tube is divided into three groups of switches, after the working temperature is reached, only one group of vulcanization insulation is retained.

4. Electric tube external terminal to avoid built-in wiring point ignition, safe and reliable.

5. The fan in the tank back and forth, the heat from the front and back evenly spread. High temperature air through a special air duct in the tank back and forth in the medium speed cycle to ensure that tank temperature uniformity, no dead ends. To solve the temperature and pressure caused by uneven product quality problems.

6. After setting the working procedures, the control system automatically heat up, maintain temperature, curing and other work, after the end of the vulcanization, the sound and light alarm and cut off the power automatically.

We also can customize the rubber vulcanizing autoclave according to your specific requirements or your drawing.

Certifications

Detailed Images

Detailed Images  Machine Parts Name: Autoclave Capped Brand: ZTD Original: China Autoclave capped is an indispensable part of the autoclave, and it is the end cap of the autoclave and is a major pressure-bearing part of the autoclave. Main Features Name:Flange

Machine Parts Name: Autoclave Capped Brand: ZTD Original: China Autoclave capped is an indispensable part of the autoclave, and it is the end cap of the autoclave and is a major pressure-bearing part of the autoclave. Main Features Name:FlangeBrand: ZTD

Original: China

Connect autoclave capped and autoclave cylinder

Machine Parts Name: Control Box

Machine Parts Name: Control BoxBrand:ZTD

Original: China

Control of the entire distribution system is a major part of the distribution box function

Main Features Name: Electric pipe

Brand: ZTD

Original: China

Produce heat source and make curing for rubber pulley,rubber hose, rubber shoes, rubber gloves, rubber v-belt and so on.

The Accessories of the Rubber Vulcanization Autoclave

The Accessories of the Rubber Vulcanization Autoclave

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

If you are interested in our products want to consult us, you can freely call us or send us Email at any time, we will be very glad to serve you. Welcome to visit our factory in Zhucheng City of China. Packing & Delivery

If you are interested in our products want to consult us, you can freely call us or send us Email at any time, we will be very glad to serve you. Welcome to visit our factory in Zhucheng City of China. Packing & Delivery  We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.Before delivery, our professional technician will do trial run for each product to check until everything is functional, you also can come to our factory and test our machine together with us.

When loading, our workers will fix the rubber autoclave tightly with wire rope so that the autoclave can't move in the container.

Our Company Shandong Zhongtaida Industrial Equipment Co. Ltd. is one of the largest and most professional manufacturers of pressure vessel vulcanizing equipment in China. Our company has complete qualifications, advanced equipment, strong technical force and complete testing means with stable quality assurance system. Main products: all kinds of small, medium and large full automatic, semi automatic, electric heating vulcanization, steam vulcanization, electric steam vulcanization , giant vulcanization, vertical vulcanization, indirect heating vulcanization, rubber vulcanization, tire retreading vulcanizing, rubber covered roller vulcanization, rubber hose vulcanization, rubber capsule vulcanization, rubber shoes vulcanization, belt vulcanization, conveyor belt vulcanization , pipeline vulcanization, cable vulcanizing tank, steam equipment and other equipment. Our company is a modern new enterprise which integrates design, manufacture and installation in one whole.

More vulcanization autoclave detail specs please check our website,

More vulcanization autoclave detail specs please check our website,www.cnmosen.com

www.CN-autoclave.com

www.ztdlhg.com

Kiki's more contact

whatsapp / wechat: +86 13371074339

Line: 86 18765175123

autoclave for shoes sole molding vulcanization, autoclave for shoes sole molding, vulcanization autoclave, shoes vulcanization autoclave autoclave horizontal industrial for pulley rubber vulcanization, autoclave horizontal industrial, pulley rubber vulcanization, pulley vulcanization autoclave

Contact us if you need more details on autoclave horizontal industrial. We are ready to answer your questions on packaging, logistics, certification or any other aspects about pulley rubber vulcanization、pulley vulcanization autoclave. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Rubber Vulcanize Autoclave

Other Products

Hot Products

Turn Waste To Wealth Recycle Tire Machine To Diesel Fuel OilSmall Used Waste Engine Oil Refinery Machine To Crude Oil FactoryDifferent capacity 10T capacity used oil distillation plant for synthetic dieselContinuous working waste drying equipment with pyrolysisHigh profitable waste tyres and plastic into diesel machineZero emission MSW treatment machine to produce electricityContinuous pyrolyze machine for the tyre and plastic to get diesel for trucksFully Automatic 30 tons Continuous Plastic Waste to oil Pyrolysis PlantHigh quality but moderate price Waste engine oil tire curde oil plastic oil distillation equipmentManufacture and supply of Used engine oil lubricate oil to diesel plantAdvanced Plastic to Diesel Plant for SalePlastic to Fuel Conversion Process Machine PricePlastic to Fuel Pyrolysis Plant ProcessPlastic to Fuel Oil Pyrolysis Plant with Advanced Conversion TechnologyNewest technology !! Rubber tire recycling pyrolysis to crude oil plantPP/PE/PS Scrap plastic recycling machine to crude oil