Large Rubber Tube Vulcanizing Tank For Rubber Hose

Product Description

Vulcanizing rubber shoes Equipment Parameter Specification:16pcs Curing Chamber for Truck Tyre

Range of Tyre Size:Within Size of 12.00-24 Truck and Passage car Tyre

Operating Worker No.:Min. 5 Staff(8 staff better)

Workshop Area:Min. 350m2

Max Service Power:100kw(Complete working)

Curing Time:220Minutes/per shift(Timing at 112°C)

Max Daily Work Shift:4ps/day

Max Daily Output:64pcs/day for within ruled max size tyre

Min Required Power:380V,50HZ.,80KW

Min Required Air Supply:0.8Mpa

Min Air Compressor:1pcs(Air Displacement:1.5m3/min;Work Prssure:1.20Mpa;Auto Power:11KW

Min Required Air Storage:1pc(Storage Volume:1M3;Work Prssure:1.25Mpa;Temperature:100°C) Vulcanizing boiler/tank-Tire/tyre Retreading Equipment * Full Auto PLC Controller vulcanizing tyres number each time: spec:16,20,22.5,24 *Semi-automatic vulcanizing tyres number each time: 1.Tank Body Packaging:High quality rock wool,glass epoxy 5mm, merits: rust-proof ,strong anti-hitting performance,good keep warm effect(each time of vulcanizing can be 15% energy conservation than the tank made from 0.05mm galvanized sheet) 2.Built-in:Anti high temperature,high pressure motor,Driving Cycling fans, 3.Oil,Electric.Air three kinds warming setup(choice freely) 4.Auto Controlling Temperature,time alarm 5.The min. tank can be feeded into 6 tyres each time The Max. tank can be feeded into 24 tyres each time Can be customized according to your output. Vulcanizing boiler/tank-Tire/tyre Retreading Equipment 1.The tyres are placed in this curing chamber and the pre-cured tread becomes adhered to the tyre through a vulcanizing process.

Our wide engineering capabilities and experience enable Zhongtaida to build chambers to suit our clients’ different preferences for size, steam heated, electric heated, or double heating system, semi-automatic and automatic chambers.

2. The power 64kw can be designed to your advice.

3. The pressure in the pot and in the package envelope fall to environment pressure which are controlled by the switch unit of zero-pressure. Automatic electric Curing chamber 12~13 tires(380V 63KW)

The production:

Product details

Product details

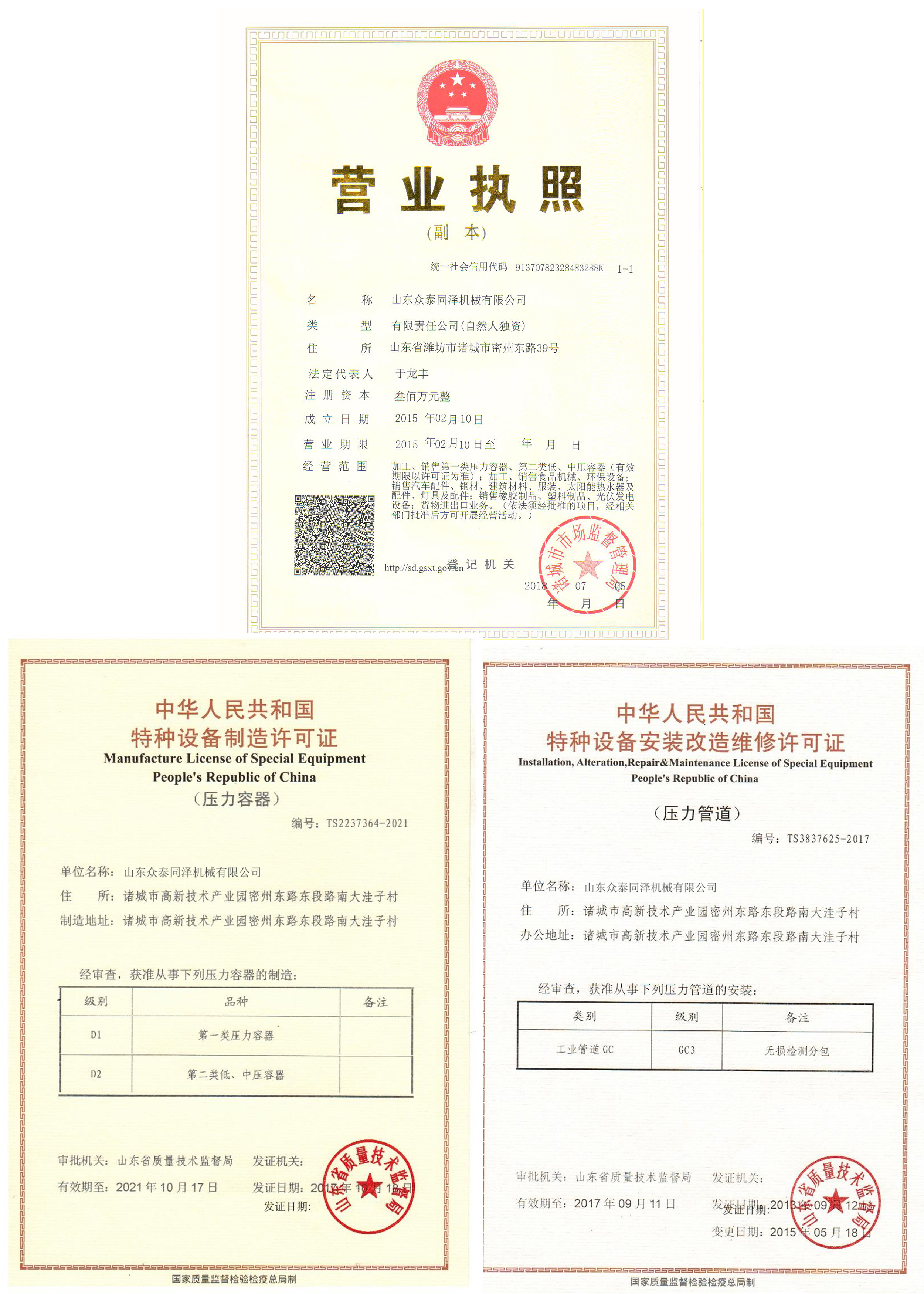

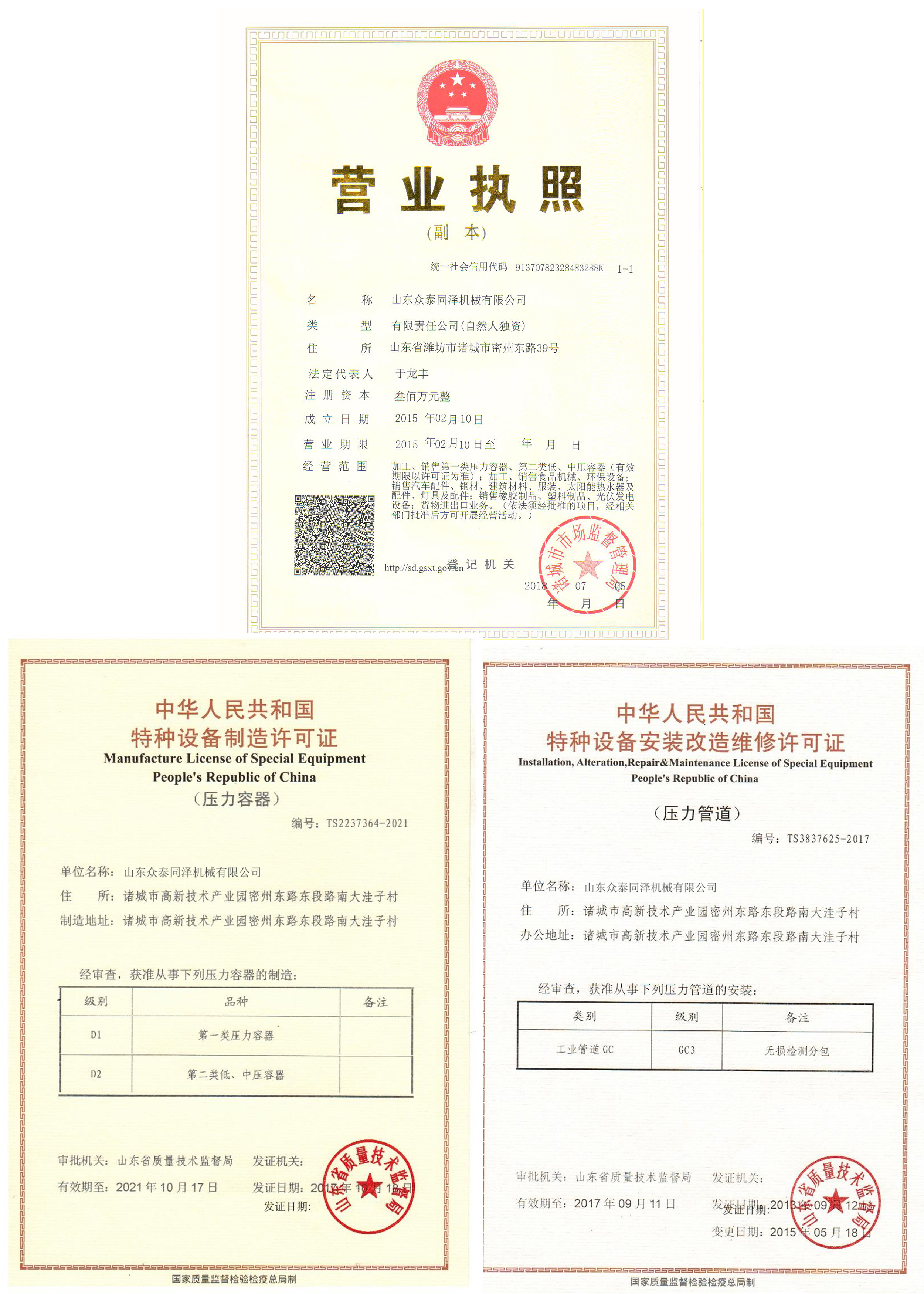

Certificate

Certificate  Workshop

Workshop  Contact us if you need more details on rubber tube vulcanizing tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vulcanization for rubber hose、vulcanizing tank for rubber hose. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on rubber tube vulcanizing tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vulcanization for rubber hose、vulcanizing tank for rubber hose. If these products fail to match your need, please contact us and we would like to provide relevant information.

Range of Tyre Size:Within Size of 12.00-24 Truck and Passage car Tyre

Operating Worker No.:Min. 5 Staff(8 staff better)

Workshop Area:Min. 350m2

Max Service Power:100kw(Complete working)

Curing Time:220Minutes/per shift(Timing at 112°C)

Max Daily Work Shift:4ps/day

Max Daily Output:64pcs/day for within ruled max size tyre

Min Required Power:380V,50HZ.,80KW

Min Required Air Supply:0.8Mpa

Min Air Compressor:1pcs(Air Displacement:1.5m3/min;Work Prssure:1.20Mpa;Auto Power:11KW

Min Required Air Storage:1pc(Storage Volume:1M3;Work Prssure:1.25Mpa;Temperature:100°C) Vulcanizing boiler/tank-Tire/tyre Retreading Equipment * Full Auto PLC Controller vulcanizing tyres number each time: spec:16,20,22.5,24 *Semi-automatic vulcanizing tyres number each time: 1.Tank Body Packaging:High quality rock wool,glass epoxy 5mm, merits: rust-proof ,strong anti-hitting performance,good keep warm effect(each time of vulcanizing can be 15% energy conservation than the tank made from 0.05mm galvanized sheet) 2.Built-in:Anti high temperature,high pressure motor,Driving Cycling fans, 3.Oil,Electric.Air three kinds warming setup(choice freely) 4.Auto Controlling Temperature,time alarm 5.The min. tank can be feeded into 6 tyres each time The Max. tank can be feeded into 24 tyres each time Can be customized according to your output. Vulcanizing boiler/tank-Tire/tyre Retreading Equipment 1.The tyres are placed in this curing chamber and the pre-cured tread becomes adhered to the tyre through a vulcanizing process.

Our wide engineering capabilities and experience enable Zhongtaida to build chambers to suit our clients’ different preferences for size, steam heated, electric heated, or double heating system, semi-automatic and automatic chambers.

2. The power 64kw can be designed to your advice.

3. The pressure in the pot and in the package envelope fall to environment pressure which are controlled by the switch unit of zero-pressure. Automatic electric Curing chamber 12~13 tires(380V 63KW)

Temperature | 112 ~ 117°C |

Capacity | 12~13 tyres |

Cure pot pressure | 0.45 ~ 0.5Mpa |

Inner tube pressure | 0.65 ~ 0.7 Mp |

Envelope working pressure | 0.2 Mpa |

Total power electricity | 63 Kw |

External dimensions (L × W × H) | 1600x2100x2100 (mm) |

Product details

Product details

Certificate

Certificate  Workshop

Workshop  Contact us if you need more details on rubber tube vulcanizing tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vulcanization for rubber hose、vulcanizing tank for rubber hose. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on rubber tube vulcanizing tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vulcanization for rubber hose、vulcanizing tank for rubber hose. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Rubber Vulcanize Autoclave

Other Products

Hot Products

Turn Waste To Wealth Recycle Tire Machine To Diesel Fuel OilSmall Used Waste Engine Oil Refinery Machine To Crude Oil FactoryDifferent capacity 10T capacity used oil distillation plant for synthetic dieselContinuous working waste drying equipment with pyrolysisHigh profitable waste tyres and plastic into diesel machineZero emission MSW treatment machine to produce electricityContinuous pyrolyze machine for the tyre and plastic to get diesel for trucksFully Automatic 30 tons Continuous Plastic Waste to oil Pyrolysis PlantHigh quality but moderate price Waste engine oil tire curde oil plastic oil distillation equipmentManufacture and supply of Used engine oil lubricate oil to diesel plantAdvanced Plastic to Diesel Plant for SalePlastic to Fuel Conversion Process Machine PricePlastic to Fuel Pyrolysis Plant ProcessPlastic to Fuel Oil Pyrolysis Plant with Advanced Conversion TechnologyNewest technology !! Rubber tire recycling pyrolysis to crude oil plantPP/PE/PS Scrap plastic recycling machine to crude oil