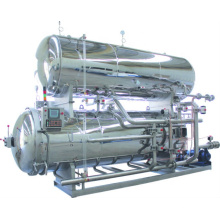

Waste Tyre Recycle To Fuel Oil Pyrolysis Machine

Product Description

Xinxiang Huayin Renewable Energy Equipment Co., Ltd

is located in Xinxiang city, Henan Province, which is specialized in manufacture waste tires/plastics to fuel oil Pyrolysis Machine and waste oil Distillation Machine since 1993. After years of research and development, we have obtained 11 patents related with our machine and also CE & ISO Certificates. Through the efforts of our domestic and international sales team, we already sold our machine to 50 different countries. 30 experienced engineers are available for domestic and overseas service. 2000 square meters Demo Plant factory have running machine could show you clear details.

The nearest airport name is Zhengzhou Xin Zheng International Airport, Welcome to visit us at any time!

Product Application

Waste tire, used rubber, waste plastic, waste cable, marine cable, PP, PE,PS of waste plastic, city waste, MSW, health waste, and medical waste , have become a big threat to our environment. Burning and landfilling make this problem much worse.

At same time, fossil energy reserves decrease ceaselessly, a lot of efforts have been made to find new substitutes. The crude oil from underground is less and less, price is higher and higher. Waste Tire/Plastic to Fuel Oil Machine not only help solve the waste problem, but also sole the energy crisis.

We would like to draw your attention to our new process and pertinent effective plant which successfully converts waste tire/plastic/rubber into furnace oil, fuel oil, carbon black and steel.

One thing we are sure about this business: it is profitable and eco-friendly.

Environmental protection

It will include four parts: water, slag, gas, noise

Water includes two parts, cooling water and de-dusting chemical water. Cooling water, just temperature higher, no pollution.

Slag, it is by-product; we can also called it carbon black. Above has mentioned the usage, please check it.

Gas includes two parts, exhaust gas and smoke dust. Exhaust gas is Methane, Ethane...these kind of gas are every easy to burning, here we make a special design could recycling it into fire furnace, heating the reactor. Smoke dust, it is generated from burning coal / wood. Through de-dusting system, it could meet the emission standard of national requirement.

Noise: under 75db.

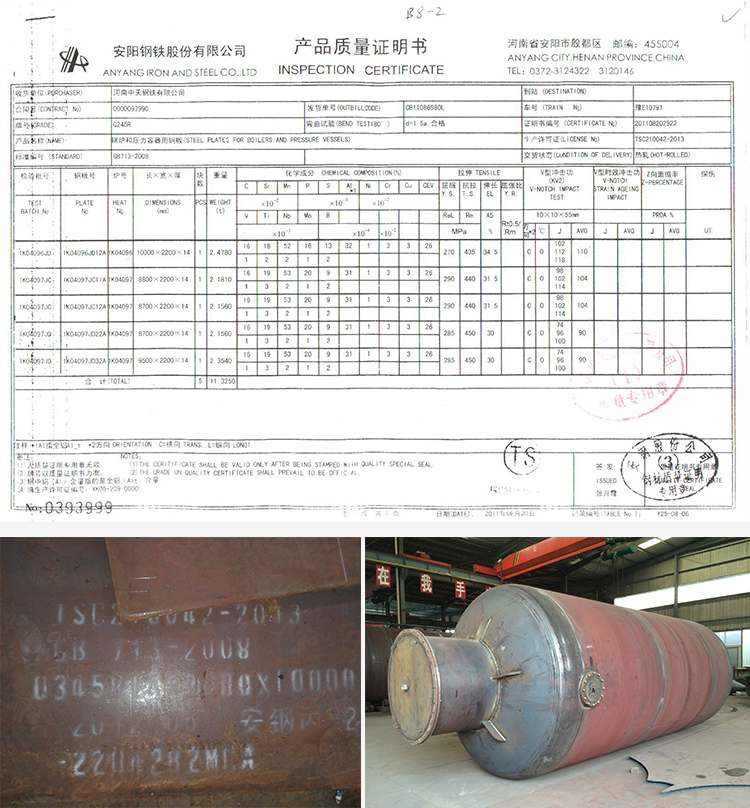

Safety devices

Our machine equipped with anti-clogging device, pressure gauges, alarming system, safety valves, negative pressure device (vacuum device), and oil-water separator.

Usually our machine is working under normal or negative pressure. In case of congestion, cause pressure, alarming system will ring, if no response from workers, safety valve could release pressure automatically.

Negative pressure device could make sure our machine working under negative pressure, more safety.

Oil-water separator could avoid oil gas go back to reactor, cause explosion.

ISO9001, ISO14001 and CE

We have got ISO9001 and ISO14001 Certifications.

And also our products are equipped with CE Certification that we have the rights to export our Waste Oil Recycling machine to European.

We also have got SGS certificate for our pyrolysis oil products you can check the oil quality features from the analysis and chose the right market for the end products.

Engineers available to the project site

Mostly one set machine needs one 40FR+ 3 * 40HQ.

Our 10 tons tire and plastic pyrolysis reactor is about 9200m *33400mm*31700mm. It is doable to take 40FR.

It is over width and over height.

And Our integrity cooling device is designed to meet 40HQ size and it is easy to ship and move the site place.

Also we adapt the hydraulic pressure for the feeding process to help hold more tires and plastic material in the fixed zone.

The auto-feeder length is about 5200mm, you can put it in one 40 HQ to ship.

As the manufacture,any questons on this recycling waste to fuel oil project will be appreciated.

Your mail will be replyed within 1 hour by our staff.

Product Categories : Waste Tire to Oil Pyrolysis Machine