High Quality Pyrolysis Oil from Waste Tires for Generators and Furnaces

Product Description

High Quality Pyrolysis Oil from Waste Tires for Generators and Furnaces can process various scrap waste tire/plastic to furnace oil for running generators and furnaces.

It's highly safe, efficient and has high oil yield thanks to our quality material of construction (Q245R/Q345R purchased from listed Anyang Iron&Steel Co., Ltd.), advanced manufacturing technology and various safety devices.

Huayin plants have been exported to to over 50 countries in the world and got highly spoken of by most clients.

With decades’ industrial experience and strong professional business abilities, Huayin R&D Center always dedicates itself to studying and developing advanced Pyrolysis and Distillation Technologies with independent intellectual property rights, providing quality engineering technology service for clients all over the world.

Huayin R&D Center continuously strengthens its exchanges and cooperation with clients, parts suppliers, universities and scientific research institutions and gradually establishes its own standardized R&D system.

Huayin R&D Center participated lots of major projects of domestic and global clients with premium quality of delivery and cooperation process being spoken highly of.

We keep committing ourselves to the development and practice of cutting-edge Pyrolysis and Distillation Technologies, providing constant vitality to the development of this industry.

Pre-sales service:

1) Providing assistance in Project Feasibility Analysis;

2) Testing sample;

3) Showing the production &demonstration site;

4) Discussing project solutions;

5) Assisting in applying governmental permit;

After-sales Service:

1) Production with our automatic production line.

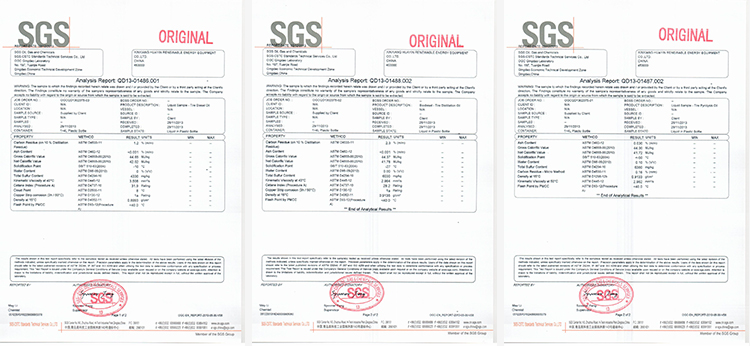

2) Quality Inspection;

3) Transportation to seaport and loading into containers:

4) Installation and Commissioning:

5) Worker training:

6) 12 months' Quality Warranty from the date of successful commissioning.

1) Is continuous pyrolysis better for us? what is the price?

A: We also have 30ton/day continuous Pyrolysis Plant which can process 30ton rubber/plastic granule (for tire, 30ton rubber granules equal to around 37ton tires because steel wire will be removed) per day and run for 30days without stopping, very large capacity. I didn’t recommend this to you at first because of its high overall cost.

Besides high plant cost of the continuous pyrolysis plant itself, tire pre-treatments machines are also required: Tires have to be cut and shredded to 3-5mm granules before being fed to the plant, meaning you’ll need tire pretreating machines as well as relevant labor, time and efforts.

2) Can we add another machines to produce electricity onsite? What is the price?

A: You mean diesel generators to produce electricity. Yes. Tire/plastic diesel can be used to produce electricity, too.

We can try find one for you. But we think you can also find diesel generators locally, so no need to buy from China and pay for the shipping cost.

3) What is the service life time of your machines?

A: For reactors, it lasts 550-750 batches. After such time, reactor may get thinner and affect its loading capacity. When it’s no longer suitable for work, you may just replace the reactor.

For other parts, service life is 5-10 years.

4) what is the best use for the carbon black we produce?

A: Carbon black has the following usages, but the most cost-effective and popular one is Solution I or II.

(1) Directly sell it to coal briquette factory, but with cheap price.

(2) Process it into carbon black pellets or briquettes for burning/heating.

(3) Further grind it to N220, N330, N550 or N660, then sell it to shoe sole factories, V-belt factory, conveyor belt factory, tire-making factory, rubber-related products factories, regenerated plastics factories, etc.

(4) Further process it into color master batch as a basic coloring material in plastic products factories, cable factories, cable jackets, underground piping etc.

5) do you have a solution for car motor waste oil?

A: Car motor waste oil, lubrication oil can be refined to diesel after going through our second-stage plants-Distillation plant and third-stage plants-Color&Smell Removal Plant.

How can we use it later?—-Diesel from car motor waste oil has same application with tire/plastic diesel.

6) If we remove the steel before the reactor it will be better?

A: Theoretically, it’s better to remove steel before feeding so that you can feed more rubbers.

But extra machines, labor and time will be needed to cut tires into several pieces and then to remove steel wire.

Through our plant, just throwing/feeding whole tires in the reactor is ok, saving your labor, time, effort and money for sure.

We can customize your High Quality Pyrolysis Oil from Waste Tires for Generators and Furnaces and other Waste to Oil Recycling Plants based on your specific needs and local conditions, so detailed communication is welcomed anytime!

Clover Feng; Mobile/WhatsApp/Wechat: +86-18137820062; Skype: cloverhappyhappy

Product Categories : Waste Tire to Oil Pyrolysis Machine