10 TPD pyrolysis plant for tyre and plastic

Product Description

10 TPD Pyrolysis Plant for tyre and plastic

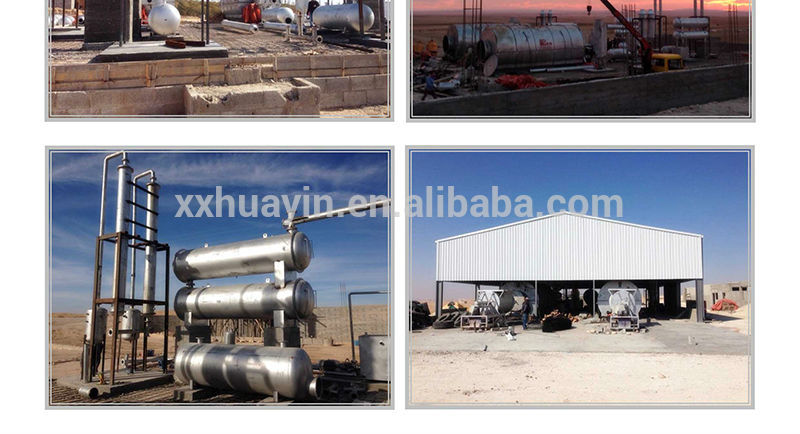

Xinxiang Huayin Renewable Energy Equipment Co., Ltd is a branch company of HUAYIN GROUP. We are specialized in manufacturing Waste Management Equipment. After years’ research, experiment and improvement, we have the honor to introduce you waste tire Pyrolysis Machine, Waste Plastic Pyrolysis Machine, waste oil Distillation Machine and decoloring device. Instead of landfill or burning, this is a green technology recycling waste tire and waste plastic to oil. HUAYIN has formal production lines with clear division of work, technical laboratory with the ability to test various parameters of oil products, experienced engineers who guarantee the installation and training of your workers. And we have different kinds of running machines in our factory. HUAYIN has professional sales team offering you honest service. We treat security as the first principle in the production, meanwhile make efforts on quality, environmental protection, automation, energy saving and high oil yield. We have certificates of ISO9001, ISO14001, CE, BV, SGS and eight patents for our equipment. HUAYIN can manufacture equipment according to your special requirements. HUAYIN is a company with Christian background. Honesty is our principle in international trade, it brings us friendships with customers and build up a fine reputation in the market. Welcome your visiting to HUAYIN. We are looking forward to have a good cooperation with you.

Waste Tire Pyrolysis plant is used to recycle waste tires to fuel oil.

Compared with landfill and burning, waste tire pyrolysis oil is a green technology and a better way for waste management.

The raw materials can be used tires, waste plastic, scrap rubber which can be easily found from rubbish collecting station.

The cost of raw materials is low, even you can get subsidy by solving pollution caused by garbage in many countries. Mean-while the fuel oil has a good market in industry field.

A. In most manufacturing processes, we replace handwork by automatic machines. On the one hand, the productions ability is increased even with less workers. On the other hand the quality of products is improved because by machine the manufacturing procedure is more accurate.

B. We choose high quality for all materials, including the plate of reactor and accessories, the motors, the shell cover, the roller, the gear, the reducer, the insulation material, the sealing material etc. We pay attention to details in each process.

| MODEL | REACTOR SIZE (Diameter*Length) (mm) | DAILY CAPACITY |

| HY-5T | 2200*6000 | 5 TON |

| HY-6T | 2200*6600 | 6 TON |

| HY-7T | 2600*6000 | 7 TON |

| HY-8T | 2600*6600 | 8 TON |

| HY-9T | 2800*6000 | 9 TON |

| HY-10T | 2800*6600 | 10 TON |

| Material of Pyrolysis Machine Reactor | Q345R/Q245R/310S+Boiler Plate/Stainless Steel |

| Thickness Of Plate | 12mm/14mm/16mm/18mm |

| Material Of Accessories | Q245B |

| Manufacturing Method | Auto-cutting,auto-rolling,auto-welding |

| Total Weight | 25-35T |

| Operating Power | 22KW |

| Space Needed (only for 1set of machin) | 300-400 square meter |

| Worker Needed | 4 |

| Condensing Mode | 3-step condenser |

| Feeding Mode | Auto-feeding |

| Input | Waste tire,plastic,rubber |

| Output | Fuel oil, carbon black,( 55245328,steel wire) |

A. Safety.We treat safety as the first important thing in production.

1) Two devices to avoid backfire in production: oil-water separator and anti-back fire device.

2) Vacuum device makes reactor working under ordinary pressure or negative pressure.

3) Temperature monitoring device to avoid excessive working temperature.

4) Pressure gage to monitor the pressure. If it goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

5) Carbon black is discharged in a closed situation to avoid catching fire.

B. Environmental protection

1) The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by dust removal device, then can be released into air through chimney.

2) The procedure to remove carbon black is working under closed situation to avoid pollution.

C. High oil yield

1. We have 3 steps for cooling system: one condenser pipe, two large horizontal condensers and two vertical condensers. The oil gas pass through 3 steps cooling system in sequence. The total cooling area is 65 square meter.

2. When the oil gas pass through the condensers, it’s divided into several portions by small pipes inside condenser and be cooled separately.

3. In this way we maximize the cooling effect and improve the oil yield.

D. High oil quality

The oil gas is purified by molecular sieve inside catalyst chamber so that the quality of oil is higher.

E. Energy saving

1) The flame path is designed as spiral so that the quantity of heat can be fully used.

2) The residual gas from pyrolysis is recycled to furnace burning to heating the reactor.

3) The insulation cover is formed by 3 levels: steel plate, rock wool and refractory cement. Excellent thermal insulation effect helps saving fuel.

F. High degree of automation

1) In manufacturing we use auto cutting machine, auto welding machine, auto rolling machine so that both quality and appearance of our products can be guaranteed.

2) In production, we use auto-feeder to feed raw materials into auto-feeder. By auto-feeder it needs few workers and less time to feed. And because of 50 ton hydraulic pressure from auto-feeder, it can feed more tires than labor.

G. Long service life

1) The material of reactor is Q345R boiler plate with 16/18mm thickness which is produced by Chinese well-known enterprise. The head of reactor and accessories are using one-piece molding shell cover rather than welded plate.

2) All cutting, rolling and welding works are finished by automatic machines.

3) We know quite well about the material quality and manufacturing process, that’s why we are confident in the service life of our products.

4) We also supply installation service, training service and one year warranty.

Contact us if you need more details on Pyrolysis Plant for Tyre. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Waste Tyre Pyrolysis Plant、Continuous Waste Tyre Pyrolysis Plant. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Waste Tire to Oil Pyrolysis Machine