Processing custom wood pressure vacuum autoclave

Product Description

#detail_decorate_root .magic-0{border-bottom-width:2px;border-bottom-style:solid;border-bottom-color:#53647a;background-color:#c5ccde;margin-left:0;margin-right:0;padding-left:8px;padding-right:8px;color:#53647a;font-family:Roboto;font-size:24px;padding-top:8px;padding-bottom:4px}#detail_decorate_root .magic-1{vertical-align:top}#detail_decorate_root .magic-2{vertical-align:top;display:block;padding-right:4px;box-sizing:border-box;padding-left:4px}#detail_decorate_root .magic-3{vertical-align:top;padding-bottom:4px;box-sizing:border-box;padding-top:4px}#detail_decorate_root .magic-4{padding:0;margin:0;white-space:pre-wrap;font-size:14px}#detail_decorate_root .magic-5{margin:0;padding:0}#detail_decorate_root .magic-6{width:750px}#detail_decorate_root .magic-7{overflow:hidden;width:750px;height:537.5px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-8{margin-top:0;margin-left:0;width:750px;height:537.5px}#detail_decorate_root .magic-9{overflow:hidden;width:750px;height:741.667px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-10{margin-top:0;margin-left:0;width:750px;height:741.667px}#detail_decorate_root .magic-11{overflow:hidden;width:750px;height:187.5px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-12{margin-top:0;margin-left:0;width:750px;height:187.5px}#detail_decorate_root .magic-13{overflow:hidden;width:750px;height:481.928px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-14{margin-top:0;margin-left:0;width:750px;height:481.928px}#detail_decorate_root .magic-15{overflow:hidden;width:373px;height:321.7250673854448px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-16{margin-top:0;margin-left:0;width:373px;height:321px}#detail_decorate_root .magic-17{overflow:hidden;width:373px;height:321.7250673854448px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-18{vertical-align:top;display:inline-block;padding-right:4px;width:50%;box-sizing:border-box;margin-bottom:-4px;padding-left:4px;margin-top:-4px}#detail_decorate_root .magic-19{vertical-align:top;box-sizing:border-box;padding-top:4px}#detail_decorate_root .magic-20{width:371px;height:200px;overflow:hidden}#detail_decorate_root .magic-21{position:relative;left:0;top:0;width:371px;height:200px}#detail_decorate_root .magic-22{padding:0;margin:0;color:#333;font-size:16px;white-space:pre-wrap}#detail_decorate_root .magic-23{padding:0;font-size:16px;line-height:20px;font-weight:bold;color:#333;margin:0}#detail_decorate_root .magic-24{padding:0;margin:0;white-space:pre-wrap;font-size:16px}#detail_decorate_root .magic-25{overflow:hidden;width:750px;height:562.5px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-26{margin-top:0;margin-left:0;width:750px;height:562.5px}#detail_decorate_root .magic-27{overflow:hidden;width:184.5px;height:203.30578512396693px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-28{margin-top:0;margin-left:0;width:185px;height:203px}#detail_decorate_root .magic-29{overflow:hidden;width:184.5px;height:203.30578512396693px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-30{margin-top:-20.33057851239669px;margin-left:-17.28099173553719px;width:203px;height:223px}#detail_decorate_root .magic-31{margin-top:0;margin-left:0;width:182px;height:201px}#detail_decorate_root .magic-32{overflow:hidden;width:184.5px;height:200.5434782608696px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-33{margin-top:0;margin-left:0;width:184px;height:239px}#detail_decorate_root .magic-34{padding:0;margin:0;color:#333;font-size:14px;white-space:pre-wrap}#detail_decorate_root .magic-35{overflow:hidden;width:750px;height:750px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-36{margin-top:0;margin-left:0;width:750px;height:750px}#detail_decorate_root .magic-37{padding:0;line-height:20px;font-weight:bold;color:#333;margin:0} Product Description Working principle: using vacuum, pressure, heating and a series of process operation, and the concentration of corrosion protection, flame retardant, dyeing liquid through a vacuum, high voltage, frequency, pressure injection of wood cell, thereby anticorrosive, mouldproof, moth-proofing, termite resistant, flame retardant, dyeing effect, etc.

Technical characteristics of wood preservative equipment/flame retardant tank/dyeing equipment:

Diameter * length: 1500mm*4000mm *8000mm.

Equipment pressure: -0.1 ~ 4.0MPa vacuum degree: 0 ~ -0.098MPa.

Design temperature: 0 ~ 180c working medium: water soluble anticorrosion, flame retardant, dyeing agent.

Process: full cell method, high low frequency pressure method, double vacuum method.

I. production process procedures:

1. Prepare medicinal liquid in the storage tank according to process production.

2, according to the product specification based - all round and select material - loading skip - open the jar - moving drive car with tank - push the skip to tank, tank door - work - vacuum liquid - frequency rehydration, pressure, pressure, discharge pressure, the liquid - after vacuum - unloading - open the tank (after being discharged pressure) -- - inspection.

II. Operation order: vacuum - impregnated - pressure - vacuum - dry.

Company Strength Zhucheng Zhongtaida Industrial Equipment Co., Ltd. is one of the largest and most professional vulcanizing tank manufacturers in China and a professional manufacturer of pressure vessels and vulcanization equipment. The company has mature technology, advanced equipment, strict management, dedicated employees, and powerful domestic and foreign cooperative manufacturers.

Company Strength Zhucheng Zhongtaida Industrial Equipment Co., Ltd. is one of the largest and most professional vulcanizing tank manufacturers in China and a professional manufacturer of pressure vessels and vulcanization equipment. The company has mature technology, advanced equipment, strict management, dedicated employees, and powerful domestic and foreign cooperative manufacturers.

Our company is engaged in domestic wood preservation tank, wood carbonation tank, optimization pot, wood impregnated wood, wood dyeing tank, wood fire-retardant pot cooking pot, wood, wood vacuum drying sets of wood processing equipment manufacturers, such as the design and manufacture of all kinds of wood processing equipment specifications, to meet the various needs of different clients.

Detailed Images Wood processing equipment and configuration:

Detailed Images Wood processing equipment and configuration:

1. Wood main tank (pressure infusion tank): tank body, quick opening tank opening, hydraulic opening and closing door device, safety interlocking device, tank inner track

2, vacuum system: vacuum pump, vacuum buffer tank

3, drainage, pressurized system: liquid pump (pressure pump)

4. Control System: Electric Control Box, System Pipeline, Instrument, Valve

5, mixing medicine, drug storage device: stirring tank, reservoir

6, outside the tank track, trolley

Heating mode: indirect steam, electric heating, direct steam, heat conduction oil heating.

Vacuum mode: vacuum pump automatically controls vacuum degree.

Pressurization: the high-pressure pump is automatically pressurized, which is higher than the rated pressure, which is lower than the rated pressure.

Time control: achieve set working time, automatic power off alarm.

Accessory Equipment

Accessory Equipment  Safety valve

Safety valve

Magnetic level gauge

Magnetic level gauge

High pressure circulating water pump

High pressure circulating water pump

Mixing tank

Mixing tank

Trolley

Trolley

Sealing ring

Sealing ring

Packing & Delivery Packing: Inner: stretch film;Outside: wood case

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.Before delivery, our professional technician will do trial run for each product to make sure no problem, you can come to our factory and test our machine together with us.

Delivery time:45 working days delivery

Our Certifications

Our Certifications

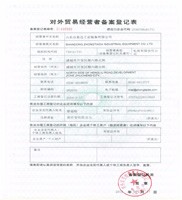

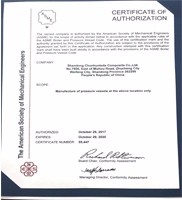

Our Certification Utility model patent certificateForeign Trade Registration Form

Our Certification Utility model patent certificateForeign Trade Registration Form

ASME certificate

Business license

Customer Photo FAQ Q: Are you trading company or manufacturer ? A: We are factory.

FAQ Q: Are you trading company or manufacturer ? A: We are factory.

Q: How long is your delivery time? A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ? A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ? A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us if you need more details on autoclave for wood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Autoclave、pressure wood autoclave. If these products fail to match your need, please contact us and we would like to provide relevant information.

Technical characteristics of wood preservative equipment/flame retardant tank/dyeing equipment:

Diameter * length: 1500mm*4000mm *8000mm.

Equipment pressure: -0.1 ~ 4.0MPa vacuum degree: 0 ~ -0.098MPa.

Design temperature: 0 ~ 180c working medium: water soluble anticorrosion, flame retardant, dyeing agent.

Process: full cell method, high low frequency pressure method, double vacuum method.

I. production process procedures:

1. Prepare medicinal liquid in the storage tank according to process production.

2, according to the product specification based - all round and select material - loading skip - open the jar - moving drive car with tank - push the skip to tank, tank door - work - vacuum liquid - frequency rehydration, pressure, pressure, discharge pressure, the liquid - after vacuum - unloading - open the tank (after being discharged pressure) -- - inspection.

II. Operation order: vacuum - impregnated - pressure - vacuum - dry.

Company Strength Zhucheng Zhongtaida Industrial Equipment Co., Ltd. is one of the largest and most professional vulcanizing tank manufacturers in China and a professional manufacturer of pressure vessels and vulcanization equipment. The company has mature technology, advanced equipment, strict management, dedicated employees, and powerful domestic and foreign cooperative manufacturers.

Company Strength Zhucheng Zhongtaida Industrial Equipment Co., Ltd. is one of the largest and most professional vulcanizing tank manufacturers in China and a professional manufacturer of pressure vessels and vulcanization equipment. The company has mature technology, advanced equipment, strict management, dedicated employees, and powerful domestic and foreign cooperative manufacturers.Our company is engaged in domestic wood preservation tank, wood carbonation tank, optimization pot, wood impregnated wood, wood dyeing tank, wood fire-retardant pot cooking pot, wood, wood vacuum drying sets of wood processing equipment manufacturers, such as the design and manufacture of all kinds of wood processing equipment specifications, to meet the various needs of different clients.

Detailed Images Wood processing equipment and configuration:

Detailed Images Wood processing equipment and configuration:1. Wood main tank (pressure infusion tank): tank body, quick opening tank opening, hydraulic opening and closing door device, safety interlocking device, tank inner track

2, vacuum system: vacuum pump, vacuum buffer tank

3, drainage, pressurized system: liquid pump (pressure pump)

4. Control System: Electric Control Box, System Pipeline, Instrument, Valve

5, mixing medicine, drug storage device: stirring tank, reservoir

6, outside the tank track, trolley

Heating mode: indirect steam, electric heating, direct steam, heat conduction oil heating.

Vacuum mode: vacuum pump automatically controls vacuum degree.

Pressurization: the high-pressure pump is automatically pressurized, which is higher than the rated pressure, which is lower than the rated pressure.

Time control: achieve set working time, automatic power off alarm.

Accessory Equipment

Accessory Equipment  Safety valve

Safety valve Magnetic level gauge

Magnetic level gauge  High pressure circulating water pump

High pressure circulating water pump Mixing tank

Mixing tank  Trolley

Trolley Sealing ring

Sealing ringPacking & Delivery Packing: Inner: stretch film;Outside: wood case

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.Before delivery, our professional technician will do trial run for each product to make sure no problem, you can come to our factory and test our machine together with us.

Delivery time:45 working days delivery

Our Certifications

Our Certifications

Our Certification Utility model patent certificateForeign Trade Registration Form

Our Certification Utility model patent certificateForeign Trade Registration FormASME certificate

Business license

Customer Photo

FAQ Q: Are you trading company or manufacturer ? A: We are factory.

FAQ Q: Are you trading company or manufacturer ? A: We are factory.Q: How long is your delivery time? A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ? A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ? A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us if you need more details on autoclave for wood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Autoclave、pressure wood autoclave. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Wood Autoclave

Other Products

Hot Products

Turn Waste To Wealth Recycle Tire Machine To Diesel Fuel OilSmall Used Waste Engine Oil Refinery Machine To Crude Oil FactoryDifferent capacity 10T capacity used oil distillation plant for synthetic dieselContinuous working waste drying equipment with pyrolysisHigh profitable waste tyres and plastic into diesel machineZero emission MSW treatment machine to produce electricityContinuous pyrolyze machine for the tyre and plastic to get diesel for trucksFully Automatic 30 tons Continuous Plastic Waste to oil Pyrolysis PlantHigh quality but moderate price Waste engine oil tire curde oil plastic oil distillation equipmentManufacture and supply of Used engine oil lubricate oil to diesel plantAdvanced Plastic to Diesel Plant for SalePlastic to Fuel Conversion Process Machine PricePlastic to Fuel Pyrolysis Plant ProcessPlastic to Fuel Oil Pyrolysis Plant with Advanced Conversion TechnologyNewest technology !! Rubber tire recycling pyrolysis to crude oil plantPP/PE/PS Scrap plastic recycling machine to crude oil