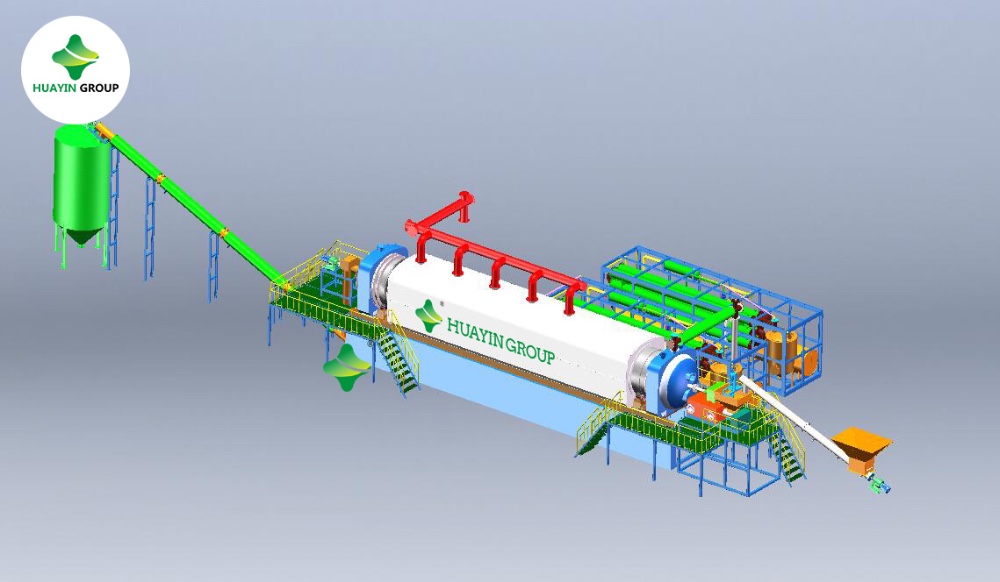

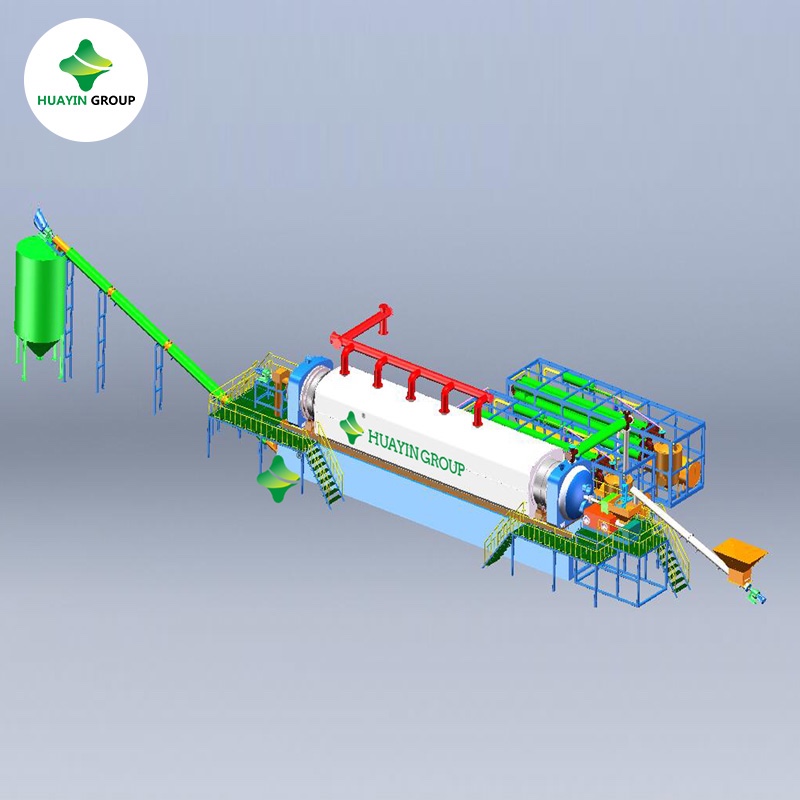

Fully Automatic 30 tons Continuous Plastic Waste to oil Pyrolysis Plant

Product Description

Fully Automatic 30 tons Continuous Plastic Waste to oil Pyrolysis Plant

automatic degree:the whole process only required 1-2 person to control, all the technica operation date is monitored and controed by the PLC.

safety aspect : the cointinuous feeding system required highly oxygen absence, N2 generator provide the N2 to make sure the whole feeding process is under safety environment, at same time the automatic discharging system can let the carbon black discharge at 200 degree, which guarnatee the carbon black quality and avoide the fire accident for the workers.

envioronmental aspect : the whoe process occured under sealing conditions , no dust fly.

Features

the equipment is equipped with explosion-proof devices, safety valves, emergency valves, pressure gauge thermometer and early warning system to ensure safe operation

Environmental Protection

Gas emissions: the use of national patent desulfurization dust removal device, can effectively remove acid gases and dust to meet the relevant national standards; emissions of smoke like steam.

The smell of production: the whole closed production, can only see the chimney discharge of white smoke, without any smell

The source material is continuously fed into pyrolysis reactor, where it is decomposed under heating in a primarily non-reactive environment.

1. Solid wastes (plastic/tyre/rubber) is fed by screw conveyor from the hopper.

2. The pyrolysis reactor is heated by the fuel burner. When the heat temperature rises to the set value, the decomposition process starts.

3. After the operation process is stable, heating is carried out by gas burner operating on pyrolysis gas.

4. From the pyrolysis reactor, the oil gas goes into condensers. Then it is cooled in the heat exchanger.

5. Oil gas enters the condenser, cools down to liquid while the non-condensed gas is used as fuel to sustain the heating process, enhancing its performance and significantly reducing operating cost.

6. The solid residue is discharged from the lower part of the reactor and shifted to receiving hoppers by the screw conveyor without oxygen access.

Guarantee on the equipment after putting into service –one year. Guarantee on the equipment from the date of shipment -18 months. Service life -10 years.

Thermal decomposition plant is equipped with online monitoring modules, requiring internet access for data recording.

Plastic Oil to Power Generator

Product Categories : Continuous Machine

Premium Related Products