Newest technology !! Rubber tire recycling pyrolysis to crude oil plant

Product Description

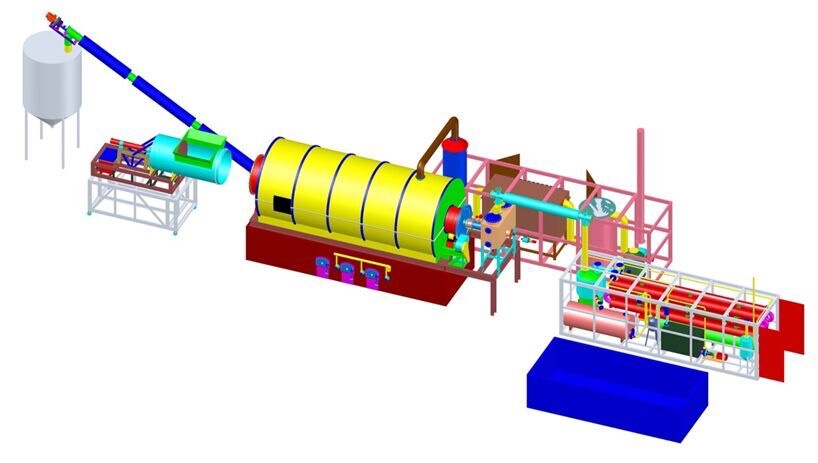

Used tires / rubbers / plastics recycling to furnace oil pyrolysis equipment

Raw material: waste scrap rubbers / tires / plastics

Pre-treatment: no pre-treatment, can feed the whole complete tires into reactor directly, no need to shred or cut the tires.

Daily capacity: 10ton complete tires per day

Working period: 22 hours per cycle

Workers: 2-3 workers during operation period

Machine installation area: 300-400 square meters

1. Ethiopia client installation site

------10ton capacity used scrap tires / tyres recycling to furnace oil Pyrolysis Machine

This is the first project the Ethiopia client build, he takes auto feeders which can help to load the non-shredded whole tires into reactor directly instead of manually, quick, safe and energy saving.

Carbon black solution: he takes the carbon black briquette machine makes all the tire carbon blacks into briquettes for heating.

Fuel for machine heating: use wood for initial heating, then recycle the produce syngas back to fire furnace for heating, energy saving.

After machine successfully running for 1 year he purchased another two sets newest design pyrolysis machine directly.

2. Thailand client installation site

-------10ton scrap plastics pyrolysis machine & 5ton Distillation Machine & de-color and de-odor system

This client use the pyrolysis technology to recycle waste plastics into diesel.

The plastics they process are mainly from household garbage center, like plastic convenient bags, farm film, very dirty.

No need to wash or clean them, can feed all these plastics waste into the pyrolysis reactor chamber directly.

The extracted diesel could be add into engines and generators directly.

3. Indonesia client installation site

-------40tons capacity scrap tires recycling to pyrolysis oil machine

This client was signed on TRADE MARK exhibition in Thailand.

In order to set up the project quickly we advise client takes our integrated design.

Thus no need to do the foundation build by themselves, all the other parts has been assembled from HUAYIN factory, totally takes two months finish all the 4 sets machine installation and training service, quick and convenient.

More and more clients prefer to choose this kind of design right now.

Further more details welcome come to contact with us soon.

Skype: gjmsunny Whatsapp: 0086-1503713067

Integrated design, all the small parts have been assembled and welded by our professional workers.

Thus, once machine arrive your place can largely shorten the installation time. Besides, during transportation can avoid the loss of small parts.

Reactor will be load onto a 40'FR container.

Reactor is the most important part of the whole system. so we assembled the inner boiler reactor and outside insulation cover together, thus once machine arrive your place, just use a crane lift it up and put on the fire furnace part should be ok.

No need you do the assemble part by yourself, convenient.

We ask our forwarder put a paulin cover the reactor to protect it from rust.

Huayin’s plants (excluding wearable parts) enjoy one-year guarantee, after which, we still offer lifelong technical support for your plant.

1.Our After-sales Service Department will pay you regular visits for any feedback, opinions or suggestions. For any question, just call: +86 371-55917087.

2.For any tiny plant problem you cannot solve after one-year guarantee finishes, please feel free to Email or call our salespeople, who will wholeheartedly help you solve your problem. For problems that cannot be solved via email or phone-call, our engineers may be dispatched to do plant maintenance and debugging (which usually takes as short as one day) until your plant resumes normal operation. Such service shall be paid at your expense after one-year guarantee finishes.

Huayin always help you succeed in this waste to Oil Recycling project by standing in your shoes: We help you choose a plant tailored to your local conditions and share our ideas on how to better manage and motivate your workers, so that you can get more unexpected gains through this business while contributing to the sole environment we rely on.

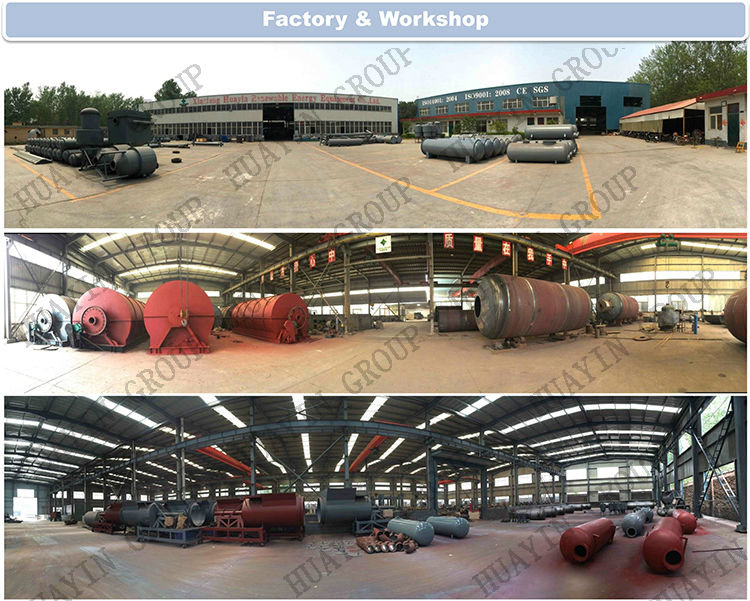

XINXIANG HUAYIN

1. Engaged in the tire / plastic recycling filed since 1993

2. Focus on the waste recycling solutions only

3. Improved our pyrolysis technology from vertical type to horizontal type, from batch type to continuous type, from distributed design to integrated design.

4. CE & ISO & SGS & BV Certificates

5. Installed pyrolysis machine in more than 46 countries all over the world

Every years have hundreds of clients came to our factory for the waste tires / plastics recycling to oil machine.

Now we have installed our machine in more than 46 country all over the world.

Welcome to visit HUAYIN !

Product Categories : Pyrolysis Plant