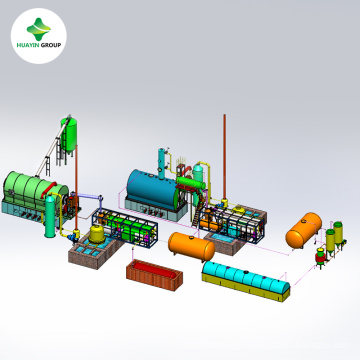

Make waste tyres/plastics treatment into crude oil manufacture

Product Description

Make waste tyres plastics to crude oil fuel oil machines are manufactured by Xinxiang huayin renewable energy equipment co,.ltd ,which is located in Kangcun Town, Huojia County, Xinxiang City, Henan Province. We are specializing in manufacturing oil refining equipment, including waste tyre to oil refining equipment, waste rubber to oil refining equipment, waste plastic to oil refining equipment and used oil refining equipment .We are the only factory who has Christian background in this field. All of our equipments have been pass ISO14001&ISO9001&CE

Features of automatic welding machine

Reactor directly decides the machine's safety and service life. It is Q345R boiler plate. The quality of welding has a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays test and heating treatment which guarantee the quality of welding ..

Cooling system:

Cooling systems decides oil output. There are three steps for cooling. Cooling pipe is the first step. The second is condenser. We have two horizontal condensers. And there are 57 pipes in one condenser. Diameter is 48mm for one small pipe. The heat exchanging area is about 26.847square meters for one condenser. So the total cooling area is about 53.7 square meters, which will guarantee you a high oil yield.

Safety:

1. Professional sealing technology for cover, oil outlet.

2. Heavy oil is separated by the oil-water separator, which can avoid the problems of jam in later condensing.

3. Vacuum system will prevent the high pressure of the reactor.

4. Alarm, safety valves, pressure gauge and a special anti-blocking device

5.It is dangerous to buning exhaust gas(C1 to C4) . In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1.The exhaust gas will be directly recycled for heating reactor, no gas pollution

2.Well water dedusting system with high pressure nozzle and environmental damper inside can avoid black smoke.

3.Every junction of the reactor is in good sealing situation with professional sealing material.

Long service life :

1.Material: Q245R special steel plate ,thickness 14mm,16mm,18mm,20mm.

2.The service life of the reactor will be 3-5 years

Energy saving:

1. The special design of fire channel can be more efficient.

2. The exhaust gas can be recycled for heating the reactor

3.the autofeeder can load the raw material no matter how hot the reactor is .

4.the shell of the reactor can seal the fire channel well,so no smoke and fire leak from the gap between the cover and the reactor.

5.the reactor was coverd by the shell ,and you can touch the shell when it is heating,so the heat preservation is very good.

Profitability analysis

Take waste tire oil refining equipment processing 10 tons for example

No. | Item | Cost of Per Batch |

1 | 10 tons of waste tires | 10T×1500RMB/T=15,000RMB |

2 | 0.4 tons of coal | 0.4T×800RMB/T=320RMB |

3 | Water and electricity | 200×1.00RMB=200RMB |

4 | Workers | 4×100RMB=400RMB |

5 | Total Cost | 15,920RMB |

NO. | Item | Income |

1 | Crude Oil | 10T×45%×4,500RMB=20,250RMB |

2 | Carbon Black | 10T×35%×520RMB=1,820RMB |

3 | Steel Wire | 10T×13%×2200RMB=2,860RMB |

4 | Gross Profit | 24,930RMB |

5 | Daily Net Profit | 24,930RMB-15,920RMB=9,010RMB |

6 | Monthly Net Profit | 9,010RMB×25=225,250RMB |

7 | Yearly Net Profit | 225,250RMB×10=2,252,500RMB |

|

|

|

Contact us if you need more details on Waste Tyres/plastics Treatment into Crude Oil. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Waste Plastics Recycling to Crude Oil、Waste Tyres/plastics Treatment into Crude Oil. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Pyrolysis Plant