Tyre Making Machine Retreading

Product Description

Overview 1. Several group of heating tube be controled seprately, low energy consumption. 2. Equipment with blower at the end of tank, make heat distribut evenly, temperature can be controled precisely. 3. The pressure and temperature can be pre-setted and pre-adjusted. 4. Using high quality thermal insulation material,which can protect workers and avoid the waste of energy . 5. High temperature silicone seal is used by the vessel door, good seal. Application It is used for vulcanizing many kinds of rubber product, include natural rubber, nitrile rubber, neoprene rubber, butyl rubber, roller, polyurethane rubber, silicone rubber, fluorine rubber, carbon fiber rubber.

FEATURES 1.Designoftank gate.Adopt manual quick open design, rapid, easy and safe. 2. High safety. Six sets of safety interlocks is adopted, includeautomatic pressure safety interlocking, pressure automatic control, manual safety, manual vent valve, high pressure alarm, automatic safety valve. Tank gate will not open as long as there have pressure inside of the chamber, remove potential safety hazard caused by mistake operation. 3. Inflatable seal. It can seal once close doorand the pot inflate, gate cannot open only when pressure reliefed totally, seal ring’s service life is more than 1 year, it wil not wear in this period. 4. Good heat preservation effect.Use aluminum silicate rock wool with steel plate support outside,which can ensure heat won’t volatilize and shape won’t transform, insulation effect can keep 10 years. 5.Automatic control: All main process can finished accurately by PLC control system, include heating process, heat preservation process, vulcanizing process, these process can realized just turn on the switch, which can save labor costs and ensure quality of product.

FEATURES 1.Designoftank gate.Adopt manual quick open design, rapid, easy and safe. 2. High safety. Six sets of safety interlocks is adopted, includeautomatic pressure safety interlocking, pressure automatic control, manual safety, manual vent valve, high pressure alarm, automatic safety valve. Tank gate will not open as long as there have pressure inside of the chamber, remove potential safety hazard caused by mistake operation. 3. Inflatable seal. It can seal once close doorand the pot inflate, gate cannot open only when pressure reliefed totally, seal ring’s service life is more than 1 year, it wil not wear in this period. 4. Good heat preservation effect.Use aluminum silicate rock wool with steel plate support outside,which can ensure heat won’t volatilize and shape won’t transform, insulation effect can keep 10 years. 5.Automatic control: All main process can finished accurately by PLC control system, include heating process, heat preservation process, vulcanizing process, these process can realized just turn on the switch, which can save labor costs and ensure quality of product.

Descriptions in detail 1. The automatic control system and semi-automatic control system are adopt by vulcanization machine, which can designed according to different customs’ need. the PLC control systemcan save more than 200 different processing technic, controlling the temperature, pressure and time accurately, so that achieve the desired effect. PLC control system can be equipped with a printer to print the temperature-time curve and pressure-time curve, the vulcanizing process can be more audio-visual and controllable.vulcanizing machine 2. Equipped with blower and windshield, making air blowing products indirectly, so as to the tank is easy to clean up. There is no dirty to pollute the rubber product which is processing, ensure the quality of the appearance of the product, the hot air evenly heating products at the same time, it is conducive to improve the quality of vulcanization vulcanizing machine Technical parameters

Descriptions in detail 1. The automatic control system and semi-automatic control system are adopt by vulcanization machine, which can designed according to different customs’ need. the PLC control systemcan save more than 200 different processing technic, controlling the temperature, pressure and time accurately, so that achieve the desired effect. PLC control system can be equipped with a printer to print the temperature-time curve and pressure-time curve, the vulcanizing process can be more audio-visual and controllable.vulcanizing machine 2. Equipped with blower and windshield, making air blowing products indirectly, so as to the tank is easy to clean up. There is no dirty to pollute the rubber product which is processing, ensure the quality of the appearance of the product, the hot air evenly heating products at the same time, it is conducive to improve the quality of vulcanization vulcanizing machine Technical parameters

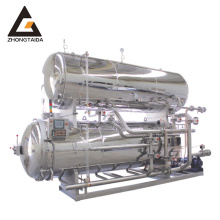

Product picture

Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Contact us if you need more details on tyre making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about retreading of tyres、tyre retreading machine cost. If these products fail to match your need, please contact us and we would like to provide relevant information.

Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Contact us if you need more details on tyre making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about retreading of tyres、tyre retreading machine cost. If these products fail to match your need, please contact us and we would like to provide relevant information.

FEATURES 1.Designoftank gate.Adopt manual quick open design, rapid, easy and safe. 2. High safety. Six sets of safety interlocks is adopted, includeautomatic pressure safety interlocking, pressure automatic control, manual safety, manual vent valve, high pressure alarm, automatic safety valve. Tank gate will not open as long as there have pressure inside of the chamber, remove potential safety hazard caused by mistake operation. 3. Inflatable seal. It can seal once close doorand the pot inflate, gate cannot open only when pressure reliefed totally, seal ring’s service life is more than 1 year, it wil not wear in this period. 4. Good heat preservation effect.Use aluminum silicate rock wool with steel plate support outside,which can ensure heat won’t volatilize and shape won’t transform, insulation effect can keep 10 years. 5.Automatic control: All main process can finished accurately by PLC control system, include heating process, heat preservation process, vulcanizing process, these process can realized just turn on the switch, which can save labor costs and ensure quality of product.

FEATURES 1.Designoftank gate.Adopt manual quick open design, rapid, easy and safe. 2. High safety. Six sets of safety interlocks is adopted, includeautomatic pressure safety interlocking, pressure automatic control, manual safety, manual vent valve, high pressure alarm, automatic safety valve. Tank gate will not open as long as there have pressure inside of the chamber, remove potential safety hazard caused by mistake operation. 3. Inflatable seal. It can seal once close doorand the pot inflate, gate cannot open only when pressure reliefed totally, seal ring’s service life is more than 1 year, it wil not wear in this period. 4. Good heat preservation effect.Use aluminum silicate rock wool with steel plate support outside,which can ensure heat won’t volatilize and shape won’t transform, insulation effect can keep 10 years. 5.Automatic control: All main process can finished accurately by PLC control system, include heating process, heat preservation process, vulcanizing process, these process can realized just turn on the switch, which can save labor costs and ensure quality of product.

Descriptions in detail 1. The automatic control system and semi-automatic control system are adopt by vulcanization machine, which can designed according to different customs’ need. the PLC control systemcan save more than 200 different processing technic, controlling the temperature, pressure and time accurately, so that achieve the desired effect. PLC control system can be equipped with a printer to print the temperature-time curve and pressure-time curve, the vulcanizing process can be more audio-visual and controllable.vulcanizing machine 2. Equipped with blower and windshield, making air blowing products indirectly, so as to the tank is easy to clean up. There is no dirty to pollute the rubber product which is processing, ensure the quality of the appearance of the product, the hot air evenly heating products at the same time, it is conducive to improve the quality of vulcanization vulcanizing machine Technical parameters

Descriptions in detail 1. The automatic control system and semi-automatic control system are adopt by vulcanization machine, which can designed according to different customs’ need. the PLC control systemcan save more than 200 different processing technic, controlling the temperature, pressure and time accurately, so that achieve the desired effect. PLC control system can be equipped with a printer to print the temperature-time curve and pressure-time curve, the vulcanizing process can be more audio-visual and controllable.vulcanizing machine 2. Equipped with blower and windshield, making air blowing products indirectly, so as to the tank is easy to clean up. There is no dirty to pollute the rubber product which is processing, ensure the quality of the appearance of the product, the hot air evenly heating products at the same time, it is conducive to improve the quality of vulcanization vulcanizing machine Technical parameters | MOLD | CONTROL | DIA (mm) | LEN (mm) | MDM | PRE (Mpa) | TEM (°C) |

| F-E10.30 | Automatic | 1000 | 3,000 | Air | 0.1~0.85 | 120~160 |

| F-E15.50 | 1500 | 5,000 | 120~160 | |||

| F-E20.80 | 2000 | 8,000 | 120~160 | |||

| S-E10.30 | Semi-autotic | 1000 | 3,000 | 120~160 | ||

| S-E15.60 | 1500 | 6,000 | 120~160 | |||

| S-E20.70 | 2000 | 7,000 | 120~160 |

Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Contact us if you need more details on tyre making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about retreading of tyres、tyre retreading machine cost. If these products fail to match your need, please contact us and we would like to provide relevant information.

Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Tyre Making Machine Retreading Contact us if you need more details on tyre making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about retreading of tyres、tyre retreading machine cost. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Tyre Cold Retread Autoclave

Other Products

Hot Products

Turn Waste To Wealth Recycle Tire Machine To Diesel Fuel OilSmall Used Waste Engine Oil Refinery Machine To Crude Oil FactoryDifferent capacity 10T capacity used oil distillation plant for synthetic dieselContinuous working waste drying equipment with pyrolysisHigh profitable waste tyres and plastic into diesel machineZero emission MSW treatment machine to produce electricityContinuous pyrolyze machine for the tyre and plastic to get diesel for trucksFully Automatic 30 tons Continuous Plastic Waste to oil Pyrolysis PlantHigh quality but moderate price Waste engine oil tire curde oil plastic oil distillation equipmentManufacture and supply of Used engine oil lubricate oil to diesel plantAdvanced Plastic to Diesel Plant for SalePlastic to Fuel Conversion Process Machine PricePlastic to Fuel Pyrolysis Plant ProcessPlastic to Fuel Oil Pyrolysis Plant with Advanced Conversion TechnologyNewest technology !! Rubber tire recycling pyrolysis to crude oil plantPP/PE/PS Scrap plastic recycling machine to crude oil